Founded in 1972 in Lukang Township, Changhua County, Taiwan, Jiten Plastics has grown into a leading manufacturer of woven and knitted plastic netting, serving both domestic and international markets with reliable, high-performance solutions.

With over five decades of experience in textile weaving and plastic mesh production, we specialize in developing engineered netting for a wide range of applications—including household insect screens, agricultural shading, windbreaks, and industrial use. Our expertise enables us to deliver consistent quality and tailor solutions to meet the specific needs of each market.

At Jiten Plastics, we are committed to quality, innovation, and sustainability. Our products undergo ROHS safety testing and are certified non-toxic, ensuring compliance with international safety and environmental standards.

As the demands of our industry evolve, we continue to invest in R&D, production efficiency, and customer collaboration. Our long-standing presence in the market is a reflection of our dedication to technical excellence, responsive service, and building lasting partnerships with clients around the world.

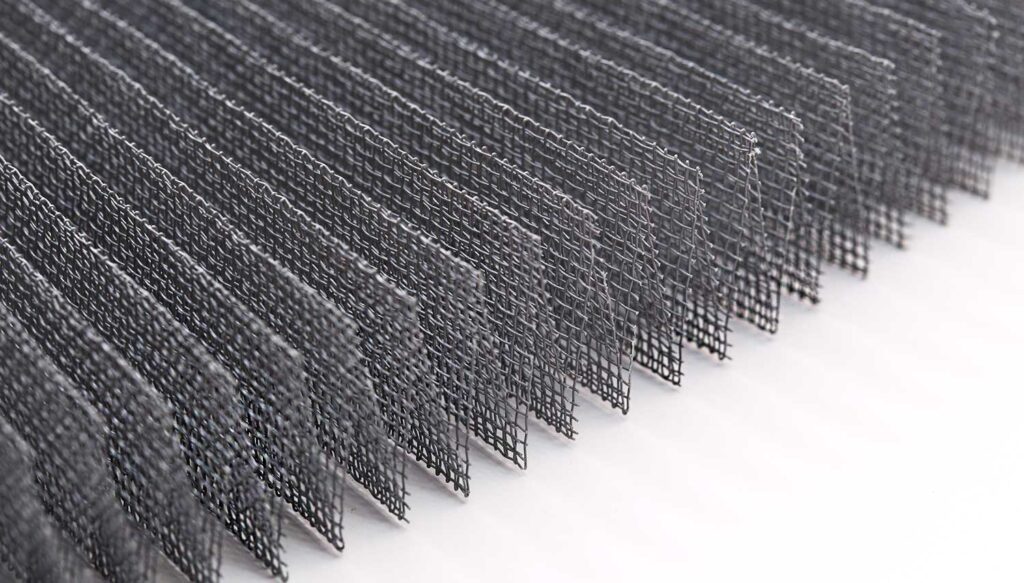

High quality PP & PE Mesh bonded at high temperature evenly-spaced, and designed for maximum performance

Leveraging five decades of experience, we provide a guarantee of long-life service and a 5-year lifespan for our expertly crafted products.

Our mesh materials are made from sustainability in mind, using eco-friendly processes and responsibly sourced materials

We offer customized sizes for our plisse mesh products, with folding heights ranging from 12mm to 30mm, ensuring a perfect fit for various applications

Product development is our responsibility—not only to maintain the highest quality in our products but also to continuously innovate

The choice of the right materials ensures we reach an excellent balance between rigidity and flexibility in our plisse mesh

Jiten Plastics began in 1972 as a small textile factory, with its initial efforts directed towards producing bandages for basic healthcare needs.

In 1980, Jiten marked its entry into the market with the launch of Anxia and Niutou screen mesh, aimed at providing insect control solutions for household suppliers and hardware stores.

After several rounds of development, pleated mesh technology was successfully introduced in 2000—significantly increasing surface area for improved filtration and screening performance, while also expanding aesthetic and installation options.

Jiten continued its innovative path by introducing PET (polyester) as a bonding material, providing customers with an additional, stiffer choice.

A new flame retardant option was launched, providing enhanced safety features.

The upcoming Anti-Haze Window Screen Mesh, scheduled for release in 2025, is designed to reduce fine particulate matter and improve indoor air quality in haze-prone environments.

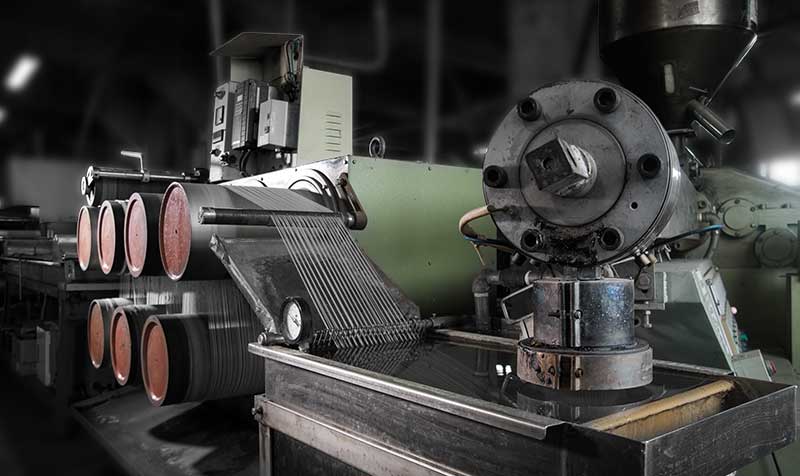

Located in Lukang City, Changhua County, Taiwan, Jiten Plastics prioritizes stringent quality control from raw materials to the final finished products. For businesses requiring reliable insect mesh, our meticulous processes ensure consistent quality. Our expert team oversees the entire production process.

Understanding diverse needs, we offer flexible quality control (QC) and quality assurance (QA) levels for your insect mesh orders. Recognizing that detailed mesh inspection demands expertise, we collaborate with you to define the optimal Acceptable Quality Limit (AQL), guaranteeing high-quality insect netting tailored to your specifications.

Our commitment includes testing of package against the manufacturing specification and agreed tolerances. This ensures the insect mesh you receive meets your exact requirements for applications ranging from agriculture to industry.

For dependable quality assurance and customizable insect mesh inspection, Jiten Plastics is your trust partner. Contact us today to discuss your specific quality control needs and request a consultation.

Jiten Plastics